Very useful evaporative cooling pad system

Why Choose Plastic Evaporative Cooling Pads? Traditional Paper Cooling Pads Face Numerous Challenges

Traditional paper cooling pads have long been the preferred choice for evaporative coolers, but they have some inherent drawbacks:

Easily Abraded:In humid environments, they are prone to mold, deformation, and scaling, leading to structural damage and typically requiring replacement quarterly.

Reduced Efficiency:With use, the pores of paper cooling pads become clogged, increasing airflow resistance and rapidly reducing cooling efficiency.

High Maintenance Frequency:Requires more meticulous maintenance and cleaning; otherwise, bacteria can easily proliferate.

Plastic Evaporative Cooling Pads:Combining Durability and High Efficiency

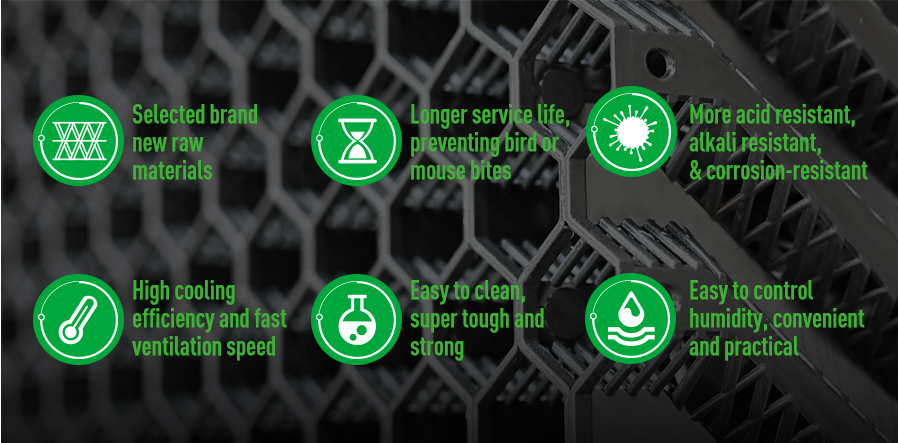

We use high-tech plastic cooling pads designed to address these pain points, representing the future direction of evaporative cooling technology.

Superior Durability and Extended Lifespan:Made from high-quality engineering plastics (such as PP polypropylene), offering excellent corrosion resistance, mold resistance, and UV resistance. They will not decompose, deform, or harbor microorganisms. With a lifespan exceeding 10 years, far surpassing any paper air conditioning pad on the market, they fundamentally reduce your long-term replacement costs and maintenance frequency.

Consistently Stable Cooling Efficiency

The unique 3D geometric corrugated design increases the evaporation surface area. The rigidity of the plastic material ensures unobstructed airflow, guaranteeing consistent cooling efficiency throughout its entire lifespan, without decreasing over time.

Easy Maintenance, Hygienic and Safe

The smooth surface of the plastic pad prevents scale buildup and allows for easy cleaning with a simple rinse or brush. Its inert surface does not easily harbor bacteria and algae, providing you with cleaner and healthier air conditioning.

Superior Water-Saving and Environmentally Friendly Performance

Due to its excellent durability, the plastic pad significantly reduces waste generation. Simultaneously, stable performance means the cooling system always operates at its optimal state, indirectly saving water resources.