WUSEN evaporative cooling pads are made of PP material.

Evaporative cooling systems have become one of the most energy-efficient and environmentally friendly solutions for managing farm temperature and ventilation. Among these solutions, plastic evaporative cooling pads represent a significant advancement over traditional materials, offering superior durability, efficiency, and sustainability—precisely what modern farms need to thrive in increasingly challenging climates.

The Science Behind Evaporative Cooling Pads

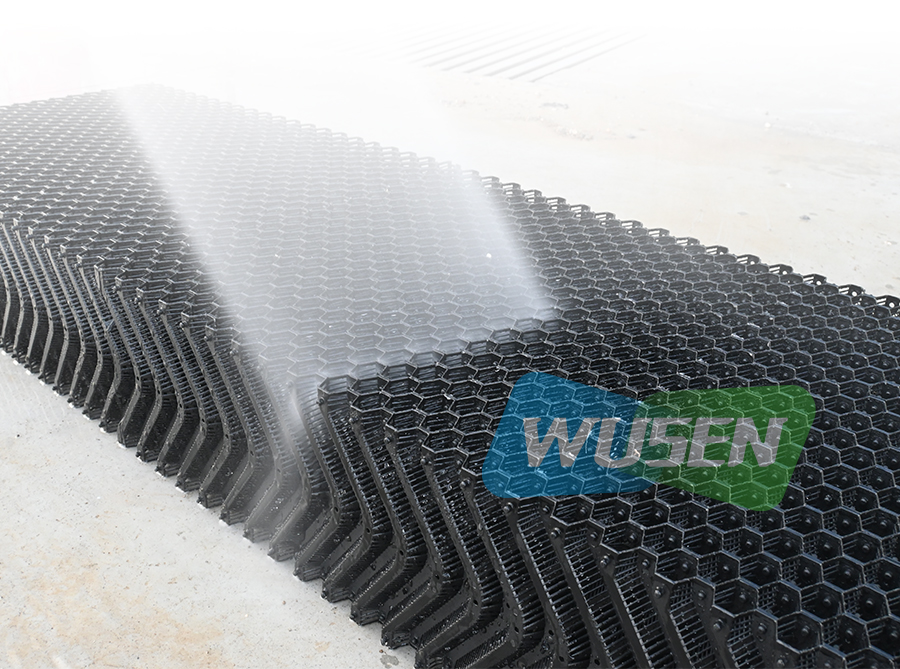

Evaporative cooling is a natural process that utilizes the evaporation of water to absorb heat from the air, effectively lowering ambient temperature. Plastic cooling pads leverage this principle by maximizing the contact area between water and air through careful design:

Large Surface Area: The cooling pad employs a specially designed honeycomb structure, creating a vast surface area that facilitates water distribution. As water flows across the pad’s surface, it forms a thin film on the honeycomb structure, allowing for optimal evaporation during airflow.

Highly Efficient Heat Exchange: When hot air is drawn into the moistened pad, the moisture evaporates, absorbing a significant amount of heat from the air. This process can lower the temperature of incoming air by 10-15°C (18-27°F), creating a more comfortable environment for livestock and poultry.

Continuous Circulation: A well-designed system includes a water pump that circulates water from the storage tank to the top of the mat, ensuring stable humidity while minimizing water consumption.

Why are plastic mats superior to traditional alternatives?

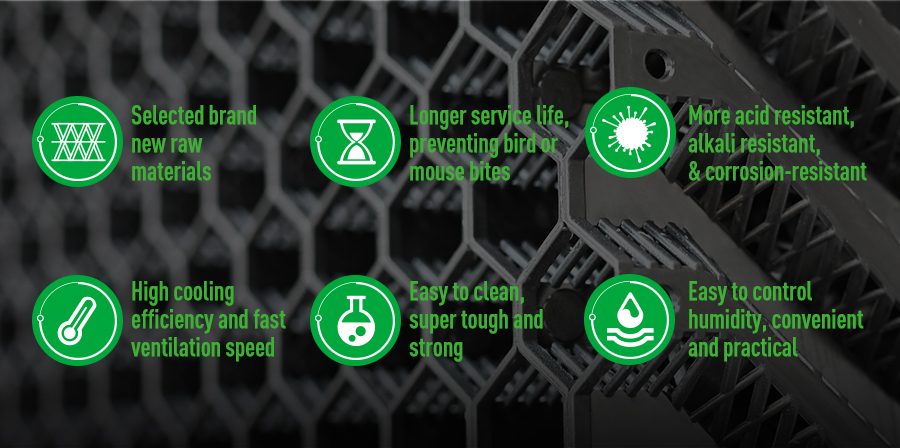

1. More Durable and Longer-Lasting

Unlike traditional cellulose mats, which age rapidly in harsh farm environments, plastic cooling mats are typically made of modified PP material, which resists:

– UV degradation from prolonged exposure to sunlight

– Chemical corrosion from water treatment agents or farm disinfectants

– Physical abrasion from continuous water flow and mineral deposits

This robust construction means a longer service life and less frequent replacements, resulting in greater long-term value.

2. Stable Performance and Low Maintenance Costs

The non-porous nature of plastic prevents mineral deposits and impurities from penetrating deep into the mat material. This means:

– Easier to clean, requiring only a simple rinse or pressure cleaning

– Reduced clogging caused by dust, algae, or water hardness

– More stable cooling performance, eliminating the need for frequent replacements

3. Customizable Design Flexibility

Plastic evaporative cooling pads are available in various thicknesses (10 cm, 15 cm) and honeycomb designs to meet specific operational needs. This allows the system to be customized to different situations:

– Farm size and layout

– Livestock type (poultry, pigs, dairy cows)

– Climate conditions